Our services

- Concept

- Design

- Calculations

- Production

- 3D CAD visualization

- Installation and comissioning

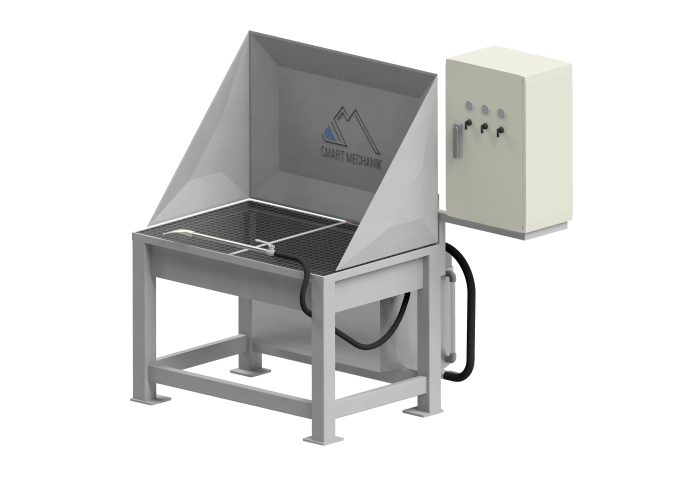

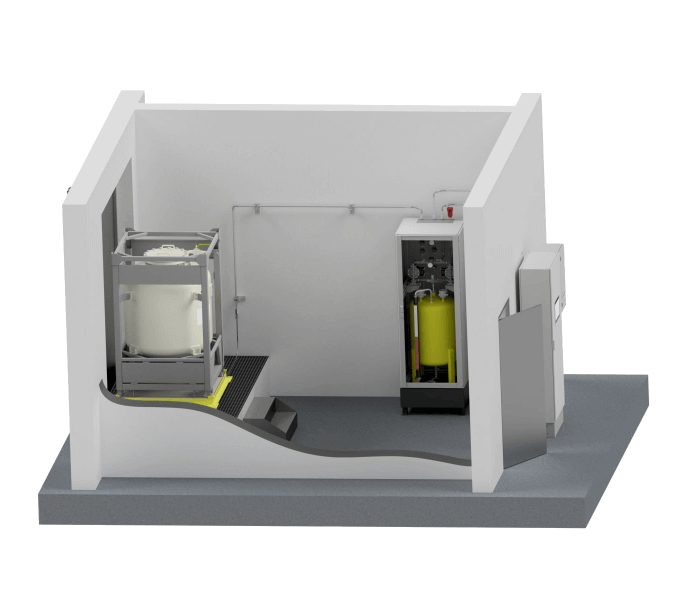

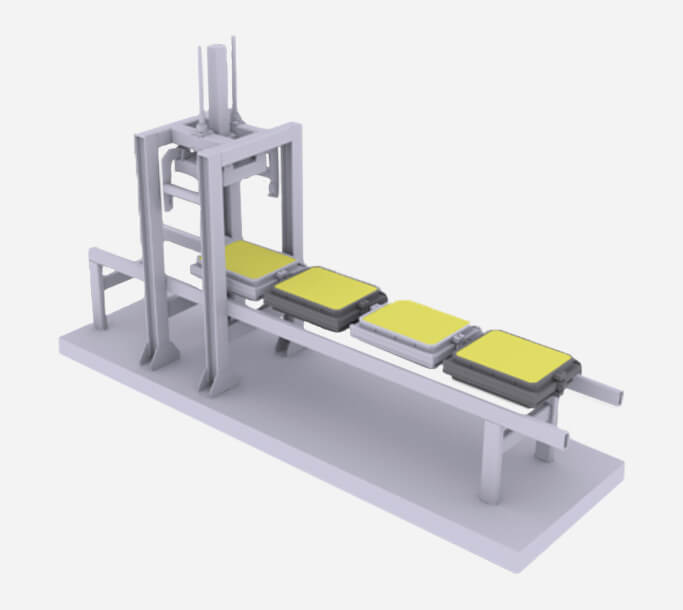

Refractory coating in the compact version driven by compressed air. Valves and drives are pneumatically controlled (optionally electrically). Complete system consisting of:

- Processing unit

- automatic viscosity control

- Pump with pulsation damper

- Flood basin with three-sided splash protection walls

- complete control and visualisation

The unit is ATEX compliant. Optionally, the use of a support, if necessary, swivelling, can be provided for mould boxes in order not to tie up lifting equipment unnecessarily. The unit can be moved as required with standard floor conveyors.